Cathy's "sewing table" is the port settee

The last 2 weeks of December were busy for us, as they are for most people, with shopping, travel and seasonal celebrations. However, in addition to the usual stuff, we embarked on a significant sewing project, making new cushions for Orion Jr. Although it took through Christmas Eve, Cathy managed to get them done, just in time to begin our celebrations – first in Florida, then NC and VA. It was a whirlwind trip that had us back to Florida on New Year's Day. So, it felt good to get this boat project done before we headed out to enjoy time with family and friends.

Original cushions on Orion Jr

New cushions for Jr

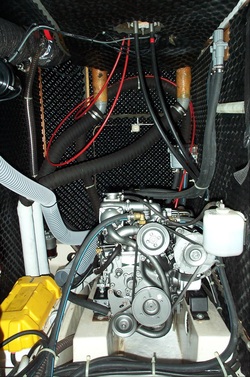

After our first season of cruising on Orion Jr, we learned what we liked and didn't like about the little boat. One source of discomfort was the settee cushions that came with the boat. The seats bottomed out and were uncomfortable, and the back rests were too far back to give support. Given the amount of time we sat there, we needed to do something to improve the seating comfort or we would both have back and neck issues before another winter was done. Making cushions was something Cathy had never done before, but she spent the summer doing some research and acquiring the fabric and most of the other supplies necessary to make the cushions once back on Jr. The design gradually evolved as we tried to accommodate not only more comfortable seating, but also maintaining access to areas behind and astern of the settees. We finally settled on 2 seat cushions per side, one of which was much smaller than the other. The smaller cushion would sit in the aftmost section of the settee, and could be easily removed to give us access to the bottom drawer in the storage cabinet on the starboard side, and to the vents to the freezer on the other side. Unfortunately, given the slope at the hull edge of each of the settees and the curve to match the hull shape, it would not be possible to make a standard rectangular seat cushion with vertical side panels. Instead the back panel (where the zipper runs) on the seat cushions would have to angle back, making patterning and construction more “interesting”. Using some cushion instructions from Sailrite and liberal advice from her friend, Pat, a plan for construction was pretty much in place as the time for construction arrived.

Once we arrived in Bradenton, Cathy began looking for a place to the get the final, and bulkiest, component of the cushions – the foam. After making a few calls, she settled on Philmore Upholstery Supply in Pinellas Park, just north of Bradenton. They were helpful on the phone and had a flexible ordering system for custom-sized rectangular cushions, which allowed us to experiment with different cushion sizes and price them out. We could also save on shipping costs and delivery time by picking them up ourselves.

After our first season of cruising on Orion Jr, we learned what we liked and didn't like about the little boat. One source of discomfort was the settee cushions that came with the boat. The seats bottomed out and were uncomfortable, and the back rests were too far back to give support. Given the amount of time we sat there, we needed to do something to improve the seating comfort or we would both have back and neck issues before another winter was done. Making cushions was something Cathy had never done before, but she spent the summer doing some research and acquiring the fabric and most of the other supplies necessary to make the cushions once back on Jr. The design gradually evolved as we tried to accommodate not only more comfortable seating, but also maintaining access to areas behind and astern of the settees. We finally settled on 2 seat cushions per side, one of which was much smaller than the other. The smaller cushion would sit in the aftmost section of the settee, and could be easily removed to give us access to the bottom drawer in the storage cabinet on the starboard side, and to the vents to the freezer on the other side. Unfortunately, given the slope at the hull edge of each of the settees and the curve to match the hull shape, it would not be possible to make a standard rectangular seat cushion with vertical side panels. Instead the back panel (where the zipper runs) on the seat cushions would have to angle back, making patterning and construction more “interesting”. Using some cushion instructions from Sailrite and liberal advice from her friend, Pat, a plan for construction was pretty much in place as the time for construction arrived.

Once we arrived in Bradenton, Cathy began looking for a place to the get the final, and bulkiest, component of the cushions – the foam. After making a few calls, she settled on Philmore Upholstery Supply in Pinellas Park, just north of Bradenton. They were helpful on the phone and had a flexible ordering system for custom-sized rectangular cushions, which allowed us to experiment with different cushion sizes and price them out. We could also save on shipping costs and delivery time by picking them up ourselves.

Cathy plans her next cut in her "workshop"

With all the supplies assembled, Cathy began patterning, starting with the port settee seat cushion. The biggest logistical issues for constructing the cushions were where to lay out the fabric for cutting and where to do the sewing. Cathy's initial plan had been to lay the material out on the docks, which are wide and smooth, but the wind quickly scuttled that idea, risking sending the fabric into the water with the first gust. At Dave's suggestion, we retreated to the laundry room, where, luckily, we never had to dodge someone using the room for its intended purpose. Once cut, we took the panels back to the boat, laid them on the foam and marked the foam for cutting. Using a highly technical cutting device, i.e., an electric carving knife, we made amazingly simple cuts of the foam along the lines. Where we had to make the angled cuts, Dave donned some heavy gloves and held the tip of the blades along the marked line, while Cathy ran the knife along the bottom edge.

Finished starboard seat cushions

With the foam cut, it was time to begin sewing. Again, the best-laid plans fell apart, since Cathy had planned to sew outside on the “social deck” tables, which were rarely used. However, the day she was ready to sew, a cold front came through, dropping temperatures and raising the wind. She instead retreated to Jr, pretty much taking over the cabin, stitching on the ice box for small things and on the sette for the bigger panels. With the sewing done, the foam was folded in half and stuffed inside the finished cover. Simple, right? Now she just had to repeat the process 5 more times. It helped that the first cushion fit well and looked pretty good

The finished product

So Cathy marched through the cushions. There were minor differences between them, but one by one, the cushions rolled off the assembly line, until they were all done. That just left the accent pillows. The end result looks pretty good and, so far, seems comfortable too. We'll see how they weather, but for now, the cabin looks much nicer.

Seeing the Sights

At the invitation of Val and Graham from Bonnie Lass, we took a trip north to Palm Harbor to visit and see their new digs. Since we had to travel north to pick up the foam anyway, we decided to make an excursion out of it and head out early to see a little of the area. So, after picking up the foam, we drove north to Tarpon Springs, which is know for its sponge harvest and the Greek community that brought this way of life to the town. The harbor has several blocks of sponge vendors and some good Greek restaurants, which managed to entice us in. In talking to one of the street vendors, we learned a little bit more about the type of sponges and how they are harvested. Apparently, the top of the sponge is sliced off, leaving the base to grow again. The “deep water” sponges are similar to those off the coast of Greece, making this a natural destination for the original Greek immigrants; We explored the city docks to learn how we might come in on Orion Jr if we made the trip by boat in the future. The city marina is right downtown and convenient to shops and dining. It would be a fun place to visit.

At the invitation of Val and Graham from Bonnie Lass, we took a trip north to Palm Harbor to visit and see their new digs. Since we had to travel north to pick up the foam anyway, we decided to make an excursion out of it and head out early to see a little of the area. So, after picking up the foam, we drove north to Tarpon Springs, which is know for its sponge harvest and the Greek community that brought this way of life to the town. The harbor has several blocks of sponge vendors and some good Greek restaurants, which managed to entice us in. In talking to one of the street vendors, we learned a little bit more about the type of sponges and how they are harvested. Apparently, the top of the sponge is sliced off, leaving the base to grow again. The “deep water” sponges are similar to those off the coast of Greece, making this a natural destination for the original Greek immigrants; We explored the city docks to learn how we might come in on Orion Jr if we made the trip by boat in the future. The city marina is right downtown and convenient to shops and dining. It would be a fun place to visit.

After our brief tour, we stopped by Val and Graham's lovely condo for dinner and a visit. With Christmas wishes and promises to listen for each other on the Waterway Net, we bid them farewell the next morning as we headed out, traveling back south along the coast. We crossed over to the barrier islands at Clearwater and re-joined the mainland again at St. Petersburg. On our journey, we managed to find a Florida winery that had a tour and tastings, and some amazing smoked fish at Ted Peters' a popular local restaurant in St. Petersburg. Overall it was a nice break before returning to sewing projects and the busy Christmas rush.

Christmas dinner on the dock

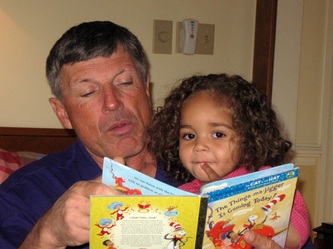

Christmas with Family and Friends

This was our first Christmas Day spent in Florida, which led to a more unusual Christmas dinner – grilling out at the marina's social deck. By Christmas Eve, David's family had arrived in Florida, and we enjoyed spending time with them, including attending two Christmas Eve services, one of which was outdoors, at our niece's church. After Christmas morning opening gifts at our niece's new home, we gathered for a feast at the marina, before heading out for NC late in the day.

This was our first Christmas Day spent in Florida, which led to a more unusual Christmas dinner – grilling out at the marina's social deck. By Christmas Eve, David's family had arrived in Florida, and we enjoyed spending time with them, including attending two Christmas Eve services, one of which was outdoors, at our niece's church. After Christmas morning opening gifts at our niece's new home, we gathered for a feast at the marina, before heading out for NC late in the day.

We were able to spend a few days in NC visiting Cathy's family and celebrating Christmas with them and Bonnie's family who traveled down from Jarratt. Although we just missed our youngest niece, we managed to have a good time with the rest of the clan.

The next stop brought us to Richmond to celebrate with Adam's family. With all 4 kids in full Christmas spirit, there was a lot of energy in the room as packages were opened. We ended our trip with a run to Hampton to check on the boat, which gave us a chance to see Steve (Bay Dreamer) and Sue (Daisy Sue) and even John (Windsong).who was in town unexpectedly. In keeping with our whilrlwind tour, we ended the day at Bonnie and Troy's to spend the night before heading back to Florida on New Year's Eve. By mid-afternoon New Year's Day, we were back on the boat, almost exactly a week since we left.