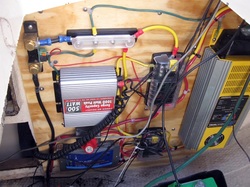

Dave put his experience on Orion to work in designing the layout of the DC power distribution and charging system. Using some components that we already had and some purchased specifically for Orion Jr, Dave constructed a DC “hub”that would hold the core elements that needed

to draw power from or return power to the batteries.

He mounted it just above the batteries on the forward bulkhead of the starboard locker, ensuring short wire runs to both batteries and the new DC

control panel.

The batteries would be charged either via the 40 amp battery charger (when hooked up to shore

power or the generator) or via the solar panels, routed through a solar controller. Both of these devices were mounted on the hub.

circuits: those always on, those on when we were at the boat, and those that would be turned on selectively when needed. In the first group, he

included the engine, the bilge pump, the battery and solar chargers, and the refrigeration. These would be clustered together on a 6-circuit fuse block, ensuring fused connections to the battery. The 2nd group of circuits which were on when we were on the boat would include lights, 12V outlets, radios, chartplotter and water pump. Since all of these devices (except the outlets) would have their own switch, they would actually not draw any power

until the individual device was turned on (or in the case of the outlets, plugged in ). They would be

clustered on another 12-circuit fuse block, which was connected to the batteries via a switch. When we return to the boat, we simply turn the switch and all of these devices would have power. The 3rd group of circuits would also only be powered when the boat power switch was turned on. However, these circuits would then be turned on selectively via a new control panel. This would have breakers to turn on the instruments, the navigation lights, the bilge pump (on-demand), the anchor / steaming light and the deck wash-down pump.

Finally, we needed to monitor the power consumption, charging input and the overall state of

the batteries. This would be accomplished with a new Victron battery monitor, mounted above the control panel in the main saloon.

With the new DC circuitry conceived, we “just” had to implement it. Dave began to assemble the necessary components with stops at Bacon Sails, Fawcett , West Marine, auto parts stores and, of course, various web vendors. In the meantime, Cathy sealed and varnished the boards that would hold the components. Then came the methodical installation and wiring of each circuit. By the end of our 3rd visit to Orion Jr, all the components were in place and functioning as designed. The final step was to buy and install new batteries, replacing the original batteries with 2 new golf cart batteries from Sam’s. With the new batteries secured in new battery boxes, the DC system was

ready to go. We were charging the batteries, running the fan (did I mention it was hot?) , watching DVD’s and turning on lights without thinking too much about it any more.

Isn’t power a wonderful thing?

Knowing that we wanted to install a furling system for the headsail, we needed to lower the mast to remove and replace the forestay with one that would work with the new furler. So, soon after arriving for

our 2nd visit to the boat, we set about lowering the mast for the first time. We were trying to decide what assistance we needed to make it work – gin poles, extra lines – when Greg (the broker who sold us the boat) arrived and told us we should be able to lower it without any extra help. So, he walked us through it and it seemed to come down smoothly. We laid it across the bow and stern rails and proceeded to remove the forestay.

projects on the mast. We needed an anchor light, since the boat did not have one. To install this, we needed access inside the top of the mast, which required removing the cap holding the sheaves

for the wire halyards. After a few consultations, Dave decided he needed to drill out the rivets holding it in place. This process went smoothly enough and with a few serious tugs, the cap was off and the inside accessible. He then installed our LED anchor light from Orion, which we would hang on the boom with a 12V plug, on the bracket holding the Windex, and ran a new wire down the mast. At the same time he ran new coax to the VHF antenna, since the old coax was pretty old and a smaller diameter than is generally used today.

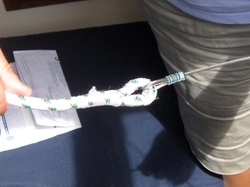

not one continuous length of line, but instead are half wire and half line. The wires looked to be in good shape, but the line needed replacing. This required creating a new braid-on-braid splice loop around the wire loop for both the main and jib halyards. Having done this only once five years before, we had to carefully read and follow the step-by-step instructions that came with the fid (a special tool used to splice this kind of line). Although the first splice took about 2 hours, we had it down pat and were able to finish the 2nd one in about a half-hour. Although I don’t think we’re going to hire ourselves out to do this professionally any time soon.

to Mayo and persuaded George to help us unroll the furler and put it in place. Before he could make a

graceful exit, however, we further persuaded him to help us raise the mast. This turned out to be a fateful decision on our part. With the mast seated in its mount on the deck, it became painfully obvious that there was no way the 2 of us would be able to raise it by ourselves without mechanical assistance. We managed to fit a ladder under it, first on the ground and then on the tailgate of George’s truck. With the help of a winch on a discarded trailer and a long halyard we had brought from Orion, George tightened the line and the 3 of us lifted to finally position it in place. We were desperately grateful to George for his help, but also re-dedicated to finding a better system for raising it in the future.

Live and learn.

Sitting around a dinner table with other cruisers, I have had more conversations about marine heads than I care to count. It’s a dirty subject, but we love to commiserate about it. So, it should be no surprise that the subject has come up again here,

where everybody can read it.

Orion Jr came with a porta-potty, which we knew we would replace. It was also plumbed with a pump-out deck fitting, 2 through-hulls for a toilet and overboard discharge and a 7-gallon holding tank.

The through-hulls both had gate valves instead of seacocks (gate valves open and close like a outdoor water faucet, making it difficult to be sure by looking at them whether they are open or closed). The holding tank was way too small to make it useful. Dave had been researching composting toilets, and we had talked to several boaters who had them on board. They allow much more time between disposing of the contents, with little

to no smell and without the additional weight of a full holding tank.

So, we decided to install the composting toilet. That meant we could have the existing through-hulls removed and glassed over. We also removed the holding tank, freeing up much needed space. We then simply installed brackets in the floor to hold the toilet in place, gave it power to run a fan to vent the composting compartment and ran a vent hose into the forward compartment. To start it up, all we need is some peat moss to begin the composting process.

The only negative about the toilet is its height. Given the raised platform in the head and the low ceiling height, let’s just say we won’t be inspired to spend much time there.

With the Electrical system, the head, and the mast in good shape, we were starting to work our way to the 2nd tier of projects to be done. We needed to

turn our attention to anchoring requirements. We had 3 anchors on board, all of whichwere danforth-style, 14lbs or less, the primary anchor on the bow being the smallest of the three. Despite the abundance of anchors, we decided to bring our little stern anchor from Orion, (also a 14 lb Danforth) along with its rode to become the new primary anchor for now. Dave also installed a new deck washdown pump, which will help keep the ground tackle clean and the associated bottom muck off the boat. He used a new thru-hull that we had Greg’s workers install on the boat when they removed the 2 gated ones. Dave then mounted the pump and its filter above the new thru-hull under the bed in the V-berth and ran the hose to the new fitting on deck, which took advantage of the old toilet vent opening. With it wired to its breaker on the control panel, all was ready for our first night at anchor.

chartplotter. We replaced the old incandescent fixtures in the Main Saloon with pairs of 6-inch LED light strips to minimize power consumption without sacrificing light intensity.

bilge pump and connect it back up. The rudder hinge had been incorrectly mounted upside down, so we corrected this, installing a wire “tether” to prevent it from accidentally slipping overboard, now that it could more easily lift up. Is there more?

Probably. But you get the idea.

June found us in Rochester, celebrating the marriage of our niece, Janelle and her fiancé, Mike.

Since our grandson was ringbearer, we had fun watching him get fitted for a tux and take charge of the cameras at the reception. A good time was had by all. After the wedding festivities were over, we got to spend some time with Joanne and Ralph of White Bird, whose new boat of that name (a beautiful Jeanneau) sails on the waters of Lake Ontario. We took a trip on the boat out to Lake

Ontario(our first time on its waters) and spent a night at their home enjoying their hospitality. It was great to see them and catch up. Who knows, we may still see them on the water in the future.

By month’s end, we expect to be have Orion Jr in the water and maybe even pointed toward Hampton. We just need some sails, some fuel, a couple of parts for the fuel system and we’ll be off. Wish us luck.