Dave at helm on way to Solomons

Orion Jr has made her maiden voyage (at least under that name), carrying us from Mayo, MD down the bay to Hampton. We finished the last of the projects necessary to get her underway as the last week in July was coming to an end. By August 1st, we were halfway to Hampton, getting the feel of this smaller boat, with her tiller and outboard engine.

Final Checklist

Probably the most significant task remaining to be done before we launched Orion Jr was to get the

fuel tanks connected to the engine. The original fuel hose needed to be replaced, and Dave also needed to find fuel tanks that would fit in the rather narrow opening for the fuel locker. Modern fuel tanks are built just a little too wide to fit. We managed to find the new fuel hose with the right fittings for the Nissan engine. Then he located 2 6-gallon tanks that fit, and at least one smaller one thanks to some help from Greg at GBS, Inc and George from Quicksilver. Then, Dave replaced the fuel line and ensured the tanks and the connections did not leak. Once the new line was run, Cathy crawled into what may be the least accessible and possible most disgusting part of the boat to tape up the gaps in the fuel vent hose. (Let’s hope the repairs hold.) With varying estimates of what the engine would use to make the run down the bay, we took on as much fuel as we could carry, which added up to about 15 gallons. This would either just get us to Solomons, 50 miles away or it would take us all the way to Hampton. Only time would tell.

Final Checklist

Probably the most significant task remaining to be done before we launched Orion Jr was to get the

fuel tanks connected to the engine. The original fuel hose needed to be replaced, and Dave also needed to find fuel tanks that would fit in the rather narrow opening for the fuel locker. Modern fuel tanks are built just a little too wide to fit. We managed to find the new fuel hose with the right fittings for the Nissan engine. Then he located 2 6-gallon tanks that fit, and at least one smaller one thanks to some help from Greg at GBS, Inc and George from Quicksilver. Then, Dave replaced the fuel line and ensured the tanks and the connections did not leak. Once the new line was run, Cathy crawled into what may be the least accessible and possible most disgusting part of the boat to tape up the gaps in the fuel vent hose. (Let’s hope the repairs hold.) With varying estimates of what the engine would use to make the run down the bay, we took on as much fuel as we could carry, which added up to about 15 gallons. This would either just get us to Solomons, 50 miles away or it would take us all the way to Hampton. Only time would tell.

New Mainsail

Before leavingAnnapolis, we went to pick up our sails. Bruce Empey, who had made the sails for

Orion, had modified the Columbia’s headsail to

make it a furling sail. The original mainsail was not worth modifying. Also, we needed to raise the boom to allow us to be able to stand under it. So, at Bruce’s suggestion, we found a new sail at Bacon that met the dimensions that he gave us for the raised boom. After we hoisted it, we discovered it

needed some modifications to the head of the sail to keep it from interfering with the backstay. Bruce had made these modifications as well.

Orion, had modified the Columbia’s headsail to

make it a furling sail. The original mainsail was not worth modifying. Also, we needed to raise the boom to allow us to be able to stand under it. So, at Bruce’s suggestion, we found a new sail at Bacon that met the dimensions that he gave us for the raised boom. After we hoisted it, we discovered it

needed some modifications to the head of the sail to keep it from interfering with the backstay. Bruce had made these modifications as well.

Orion Jr has tiller-steering, and the boat’s tiller had obviously been through a lot over the years, given its state when we purchased the boat. So, one of our first projects was to bring it back to Hamptonand work on re-finishing it. Cathy prepped and sanded it, which was all most of the surface needed. However, there was a hole in the side near the tip, with a repair that was failing. So, Dave used some epoxy to fill the hole, making it stronger than new. It also looks not much different from a knot in the wood. Several coats of varnish later, the tiller gleamed. With a couple of bolts through the end, it was re-installed and the boat was ready to steer.

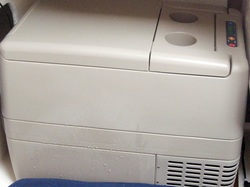

New freezer

With several days of travel ahead, we decided to use the trip to try out our new Waeco fridge / freezer. It fit perfectly on an aft settee, just tight enough not to move while underway. Dave wired it into the fuse block and we started freezing 2 liter bottles of water to use as ice for the ice box. With our arrival several days later in Hampton, we were still working out a process that consumed the least amount of amps, but we had learned a lot.

Just a few more things to do. Dave needed to replace the hose for the new manual bilge pump and he also added a strainer to the bilge end of the run. Cathy had spent the last hiatus in Hampton making curtains for the portlights and to separate the Main Saloon and V-berth. We had purchased plastic h-track from a local canvas shop and, with some advice from Dan at Sailrite in Annapolis, we used a strong double-sided tape to mount them. They help provide privacy and help reduce the heat in the cabin below. And they don’t look too bad either.

The rest of the time, we spent organizing things down below, removing anything we could and stowing the remaining debris in various nooks and crannies. We had wanted to apply the name decals to the hull before launch, but alas they hadn’t arrived. We would just have to find a way to do it in the water. Other than that, by end of the day Wednesday, we felt we were ready to go.

The rest of the time, we spent organizing things down below, removing anything we could and stowing the remaining debris in various nooks and crannies. We had wanted to apply the name decals to the hull before launch, but alas they hadn’t arrived. We would just have to find a way to do it in the water. Other than that, by end of the day Wednesday, we felt we were ready to go.

Orion Jr ready to launch

Into the Water – and out again

Our launch was scheduled for Thursday morning (July 28th), and we felt we were ready. We surveyed the bottom of the boat for any last minute items to take care of. We realized the speed thru-hull needed paint around its rim, which Dave quickly applied. He was concerned that he couldn’t be sure whether the depth transducer had bottom paint on it. So, he had the boatyard sand it down and put the transducer-specific paint on it. Cathy pulled the few remaining items out from under the boat, to leave it clear for the Travelift bands. We

opened up the compartments in the V-berth that contained our new and existing thru-hulls, to make inspection easier once we were lowered in the water. By late morning, she was underway to her launch. We arranged to have her lowered only partway into the water at first to allow us to get on board and check the thru-hulls. And it was good that we did. Although all the thru-hulls were sound, including the new one, there was a tiny leak through the fiberglass seal that covered the opening of a thru-hull that had been removed. It looked like we weren’t going any further into the water today.

Our launch was scheduled for Thursday morning (July 28th), and we felt we were ready. We surveyed the bottom of the boat for any last minute items to take care of. We realized the speed thru-hull needed paint around its rim, which Dave quickly applied. He was concerned that he couldn’t be sure whether the depth transducer had bottom paint on it. So, he had the boatyard sand it down and put the transducer-specific paint on it. Cathy pulled the few remaining items out from under the boat, to leave it clear for the Travelift bands. We

opened up the compartments in the V-berth that contained our new and existing thru-hulls, to make inspection easier once we were lowered in the water. By late morning, she was underway to her launch. We arranged to have her lowered only partway into the water at first to allow us to get on board and check the thru-hulls. And it was good that we did. Although all the thru-hulls were sound, including the new one, there was a tiny leak through the fiberglass seal that covered the opening of a thru-hull that had been removed. It looked like we weren’t going any further into the water today.

Re-painting depthsounder

After Greg (who had done the work) inspected the leak, he determined that the water had found a tiny channel through the fiberglass, which was the source of the droplets of water. So, we hauled the boat back out of the water, and he put another layer of epoxy on the outer hull and more fiberglass on the inner hull. To give the repair the best chance, we delayed re-launch until Friday morning. Dave would apply the bottom paint to the epoxy on the hull in the morning, just before we splashed. We just hoped there would be no more leak. We then left the boat in the bands overnight and traveled to see George and Gail, who were going to keep the car for us and bring us back early the next morning. Shortly after arriving back at the marina, Dave had applied the paint and we were going back in the water. This time, all was dry. Orion Jr was in the water where we could finish preparing her for the shakedown cruise the next day.

Removing bubbles from the new name

The delay in launching wasn’t all bad, since the boat name decal that we ordered on-line arrived Thursday morning. With the boat back out the water, we had the time to apply it. So, we spent an hour applying the name to each side of the hull. In

retrospect, this is not something we would have liked to have done with the boat in the water. The results look pretty good, and Orion Jr is now official.

retrospect, this is not something we would have liked to have done with the boat in the water. The results look pretty good, and Orion Jr is now official.

Maiden Voyage

The rest of Friday was spent checking out boat systems that we couldn’t do on land. The depth

sounder worked and seemed accurate, which we verified by dropping a lead line. Dave’s new deck washdown pump and associated plumbing worked great after he tightened a screw on a hose clamp. Cathy managed to rig some temporary shade over the boom. It would keep us from raising the main, but would keep us out the sun and cooler

than without it until Cathy could build the bimini in Hampton. Dave started the engine (easily) and checked the fuel lines for leaks (none were found). We also spent some time re-distributing weight on the boat. While in the bands, the lift operator told us that we had only about 1000 lbs forward, but 3500 aft. So, we stowed some lesser used items in the V-berth compartments under the cushions. Finally, we washed the outside of the boat, which had gotten pretty dirty from its weeks on the hard. With our work done, there was little we could do, but try to escape the boiling 102 degree heat of this last Friday in July. As the sun

began to set, we started to get some relief. We made an early night, so we could leave at first light for Solomons.

The rest of Friday was spent checking out boat systems that we couldn’t do on land. The depth

sounder worked and seemed accurate, which we verified by dropping a lead line. Dave’s new deck washdown pump and associated plumbing worked great after he tightened a screw on a hose clamp. Cathy managed to rig some temporary shade over the boom. It would keep us from raising the main, but would keep us out the sun and cooler

than without it until Cathy could build the bimini in Hampton. Dave started the engine (easily) and checked the fuel lines for leaks (none were found). We also spent some time re-distributing weight on the boat. While in the bands, the lift operator told us that we had only about 1000 lbs forward, but 3500 aft. So, we stowed some lesser used items in the V-berth compartments under the cushions. Finally, we washed the outside of the boat, which had gotten pretty dirty from its weeks on the hard. With our work done, there was little we could do, but try to escape the boiling 102 degree heat of this last Friday in July. As the sun

began to set, we started to get some relief. We made an early night, so we could leave at first light for Solomons.

Cathy rigging temporary shade

As dawn came, we were already up and preparing to move. Although we had started the engine the

day before, we hadn’t used it to move the boat, and it had been several years since we had used a tiller to steer a boat. It was going to be a learning process, but we had several days of sailing ahead to get used to it. So, we pushed off the dock and made our way down Cadle Creek to the RhodeRiver, site of our first grounding on Orion. Our only company this early on a Saturday morning was some crabbers and the fishermen headed out to the bay. Dave had rigged our trusty Garmin 172C chartplotter with a temporary mount to guide us on our journey. As we entered the West Riverand approached the bay, we took our first shortcut across the shoal at its entrance. Something we would never had tried with Orion. Once on the bay, we realized the wind was going to give us a nice push, so we unfurled the headsail and began to

motorsail. As the day progressed, the wind built, but how much we couldn’t say, since this boat has no anemometer. But the whitecaps and the waves behind us told us it wasn’t the 5-10 knots forecast. So, we shut off the engine and sailed on the headsail alone for the remainder of the trip down the bay, only furling the sail when we entered the mouth of the Patuxent.

Since we had no dinghy on board, we decided to take a spot on a dock so we could visit with Dave’s cousins in LexingtonPark. The first docking went fine in nearly calm conditions on a face dock. Not the biggest challenge, but every successful docking is a victory. After a couple of days

spent with Don and Cindy and family, we headed out early on Monday for the Great Wicomico River, just south of the Potomac. After a morning of virtually no wind, which we appreciated as we crossed open waters of the mouth of the Potomac, the wind began to build out of the south, which was (of course) the direction we were heading. The smaller boat was slowed considerably more by pounding into the waves than our big boat. At one point, the outboard popped up out of the water, the mount no longer staying down. Later, we learned this was because we hadn’t locked the mount in the down position.

day before, we hadn’t used it to move the boat, and it had been several years since we had used a tiller to steer a boat. It was going to be a learning process, but we had several days of sailing ahead to get used to it. So, we pushed off the dock and made our way down Cadle Creek to the RhodeRiver, site of our first grounding on Orion. Our only company this early on a Saturday morning was some crabbers and the fishermen headed out to the bay. Dave had rigged our trusty Garmin 172C chartplotter with a temporary mount to guide us on our journey. As we entered the West Riverand approached the bay, we took our first shortcut across the shoal at its entrance. Something we would never had tried with Orion. Once on the bay, we realized the wind was going to give us a nice push, so we unfurled the headsail and began to

motorsail. As the day progressed, the wind built, but how much we couldn’t say, since this boat has no anemometer. But the whitecaps and the waves behind us told us it wasn’t the 5-10 knots forecast. So, we shut off the engine and sailed on the headsail alone for the remainder of the trip down the bay, only furling the sail when we entered the mouth of the Patuxent.

Since we had no dinghy on board, we decided to take a spot on a dock so we could visit with Dave’s cousins in LexingtonPark. The first docking went fine in nearly calm conditions on a face dock. Not the biggest challenge, but every successful docking is a victory. After a couple of days

spent with Don and Cindy and family, we headed out early on Monday for the Great Wicomico River, just south of the Potomac. After a morning of virtually no wind, which we appreciated as we crossed open waters of the mouth of the Potomac, the wind began to build out of the south, which was (of course) the direction we were heading. The smaller boat was slowed considerably more by pounding into the waves than our big boat. At one point, the outboard popped up out of the water, the mount no longer staying down. Later, we learned this was because we hadn’t locked the mount in the down position.

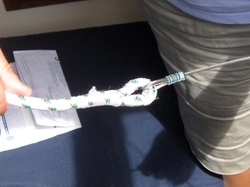

Dave deploying anchor at Sandy Point

With thunderstorms in the forecast, we wanted to make it into our anchorage before they arrived. Turning into the Great Wicomico, the waves moved to the beam and Orion Jr wallowed with the swells until we rounded Sandy Point and made it into the protection of its shoal. After 2 attempts, we managed to get the danforth anchor to set. It was a different process, since the anchor rode was in a bag, consisted of only 10 ft of chain and the rest rope, and without a windlass it had to be hauled in each time by hand. Cathy had to reach back to the outboard to shift into reverse or dash forward to the chartplotter to set the anchor drag and read how far we had fallen back. With only one other boat in the anchorage and a lot of room to shore, we felt we could handle the storms when they came.

After a short while at anchor, our neighbors on La Comete came over to invite us for a visit. We took them up on their offer and met this wonderful family of 5 (children ranging from 12 to 3) who were on their way to Quebec to have their boat hauled. They had started out in France in 2006, and spent several years in the Caribbean. We shared information about destinations in the bay, but warned them not to expect a lot of good sailing in the Bay in July – words that would come back

to us later in our trip. As the lightning began to fill the sky, we begged our leave and headed back to the boat to brace for its arrival. When nothing happened for several hours, we began to think we’d dodged a bullet. But not so. The wind started blowing and was putting a large strain on our temporary shade. So, in the dark and bounced by the wind, we scrambled to untie it and take it down. A quick glance at the chartplotter in the process said the boat was OK, but once the shade was down, a look around made it obvious that we had dragged. So, we fired up the engine and moved into the wind far forward of our position, so we could fall back or (God forbid) drag a long way. We managed to get the anchor to set after a bit, and it held for the rest of the night, even making it hard to pull out in the morning.

The storm cooled things off, and we had a pleasant sail to Indian Creek where we visited with Joy and Rusty from Slow Dancin’. After a weather day (which netted Dave his first ground tackle upgrade – 70 ft of chain), we moved down the bay and decided to use the north winds to push us all the way to Hampton. With a late start, this at first seemed doubtful, but by motorsailing and with a little push from the current, we pulled into our slip before 7pm, a long 10-hour run, but feeling

good to be back home.

After a short while at anchor, our neighbors on La Comete came over to invite us for a visit. We took them up on their offer and met this wonderful family of 5 (children ranging from 12 to 3) who were on their way to Quebec to have their boat hauled. They had started out in France in 2006, and spent several years in the Caribbean. We shared information about destinations in the bay, but warned them not to expect a lot of good sailing in the Bay in July – words that would come back

to us later in our trip. As the lightning began to fill the sky, we begged our leave and headed back to the boat to brace for its arrival. When nothing happened for several hours, we began to think we’d dodged a bullet. But not so. The wind started blowing and was putting a large strain on our temporary shade. So, in the dark and bounced by the wind, we scrambled to untie it and take it down. A quick glance at the chartplotter in the process said the boat was OK, but once the shade was down, a look around made it obvious that we had dragged. So, we fired up the engine and moved into the wind far forward of our position, so we could fall back or (God forbid) drag a long way. We managed to get the anchor to set after a bit, and it held for the rest of the night, even making it hard to pull out in the morning.

The storm cooled things off, and we had a pleasant sail to Indian Creek where we visited with Joy and Rusty from Slow Dancin’. After a weather day (which netted Dave his first ground tackle upgrade – 70 ft of chain), we moved down the bay and decided to use the north winds to push us all the way to Hampton. With a late start, this at first seemed doubtful, but by motorsailing and with a little push from the current, we pulled into our slip before 7pm, a long 10-hour run, but feeling

good to be back home.

So, we had made our shakedown cruise and learned a few things about life on Orion Jr.

1. We can travel much closer to points on shore, cutting corners, which makes the distances shorter.

2. There is more motion on the little boat, meaning we need to watch the weather and travel in lighter winds.

3. The radio, depthsounder, engine, sails, fuel, and electrical systems worked well.

4. The boatspeed doesn’t work at all and the compass doesn’t read correctly.

5. The fuel economy was a LOT better than forecast.

6. Our trip to Solomons consumed only 2 gallons and from Solomons to Indian Creek took only 4.5.

7. We need an auto-pilot.

8. The weather forecast for every day we traveled, except one was for winds at 5 – 10 knots, however, without exception, each day we had whitecaps and 3ft seas. We keep wishing we

could take back the advice we gave the folks on La Comete.

Friends and Family

1. We can travel much closer to points on shore, cutting corners, which makes the distances shorter.

2. There is more motion on the little boat, meaning we need to watch the weather and travel in lighter winds.

3. The radio, depthsounder, engine, sails, fuel, and electrical systems worked well.

4. The boatspeed doesn’t work at all and the compass doesn’t read correctly.

5. The fuel economy was a LOT better than forecast.

6. Our trip to Solomons consumed only 2 gallons and from Solomons to Indian Creek took only 4.5.

7. We need an auto-pilot.

8. The weather forecast for every day we traveled, except one was for winds at 5 – 10 knots, however, without exception, each day we had whitecaps and 3ft seas. We keep wishing we

could take back the advice we gave the folks on La Comete.

Friends and Family

On our way to the boat, we visited with our son’s family for a few days, getting to babysit some and enjoy the kids. We also spent time with Don and Cindy and the kids, enjoying their hospitality and helping the kids with their search for a new dog.