Once we made it back into the water, it wasn’t long before we were on the move – and moving quickly. We left Deltaville on the 26th of October and were spending Halloween on the sea wall in Elizabeth City. We’ve moved on since then, but this entry will catch you up on how we finally took Orion off her jack stands and set her afloat again after more than 2 months of land sailing and boat projects.

It was a long wait, but the rudder was finally re-installed.

Steering With a Rudder (Finally)

It was becoming a constant topic of conversation. Every time someone asked when we were going to get launched, we would point to the rudder lying on its side beneath the boat and say, “we’re waiting for that to go back on”. Oh, I see was usually the reply. Although it’s possible to steer with the sails, we prefer the comfort of knowing that a turn of the wheel will actually turn the boat. It had been a bit of a rocky road, so we weren’t sure how smooth the final installation would go.

The first little hiccup occurred during the rudder removal. While Orion was still in the Travel Lift bands, hoisted up to allow room to remove the rudder post, a piece of the rudder quadrant broke during the process of removing the pin to drop the rudder. The stainless steel pin had frozen in the cast aluminum rudder quadrant, making it difficult to remove. After reviewing our options for a repair, we decided to have a replacement part machined in Deltaville.

It was becoming a constant topic of conversation. Every time someone asked when we were going to get launched, we would point to the rudder lying on its side beneath the boat and say, “we’re waiting for that to go back on”. Oh, I see was usually the reply. Although it’s possible to steer with the sails, we prefer the comfort of knowing that a turn of the wheel will actually turn the boat. It had been a bit of a rocky road, so we weren’t sure how smooth the final installation would go.

The first little hiccup occurred during the rudder removal. While Orion was still in the Travel Lift bands, hoisted up to allow room to remove the rudder post, a piece of the rudder quadrant broke during the process of removing the pin to drop the rudder. The stainless steel pin had frozen in the cast aluminum rudder quadrant, making it difficult to remove. After reviewing our options for a repair, we decided to have a replacement part machined in Deltaville.

Although the machinist didn't provide estimates, we were given a "ballpark" figure for the work. When the part arrived, it was well-crafted, but we were taken aback when the final cost came in over 3 times the ballpark figure he had given the boatyard. Thankfully for us, Matt helped us with the overall cost of the rudder repair, minimizing the impact of the machined part's cost. With it in hand, we were ready to replace the faulty o-ring and re-insert the rudder. Unfortunately, this process didn’t go smoothly at all. Every attempt to position it correctly was frustrated by the tightness of the opening. The o-ring would roll over as the rudder was inserted. After Matt inspected the process personally, he called for a break.

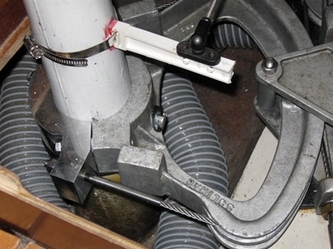

Inserting the o-ring from below, it kept rolling out of position.

In preparing a path forward, we did more work on the rudder to hopefully ensure a smoother installation. We polished the stainless steel band that sits just above the rudder until it shone. The boatyard put fiberglass on the post above the band so that the transition from the post to the stainless steel was smooth. The bronze bushing was removed and polished and the opening within the boat was cleaned and polished to ensure it was smooth with no obstructions. The first attempt to install the o-ring had nicked it, so we ordered another, but it had to come from France.

Matt supervised the 2nd attempt to re-install the rudder.

A couple of weeks later, the prep work was completed, and the o-ring was in hand, so a second install was scheduled. This attempt proved more successful than the first. However, the approach was completely different. With information received from Beneteau in France, the plan was to insert the o-ring from above. After carefully measuring the distance from the top of the rudder tube to the o-ring’s standard position, a wooden stick was cut and marked to assist in positioning the o-ring and ensure it was at the right location. With 2 people holding the rudder below, Dave on deck to insert the upper pin to hold the rudder and 2 people below decks to insert the o-ring, the installation began again. This time the process worked as planned. The o-ring stayed seated in place. We were golden – or maybe not quite.

Since this was a more unusual installation, Matt insisted the rudder quadrant be installed after we were in the water, so he could check the rudder for leaks and look down into the rudder shaft. He wanted to be able to turn the rudder, but without the quadrant, the wheel couldn’t be used. So, Dave dug out our emergency tiller, which we got to use for the first time. After turning the rudder through its entire arc several times with no problems, we had passed the next hurdle. So far, so good

Since this was a more unusual installation, Matt insisted the rudder quadrant be installed after we were in the water, so he could check the rudder for leaks and look down into the rudder shaft. He wanted to be able to turn the rudder, but without the quadrant, the wheel couldn’t be used. So, Dave dug out our emergency tiller, which we got to use for the first time. After turning the rudder through its entire arc several times with no problems, we had passed the next hurdle. So far, so good

We just had to have the rudder quadrant installed and then the take her out for a sea trial. The quadrant was on that afternoon, and we headed out the next morning for the sea trial. It looked good. No water by the rudder. We decided to head out for Mobjack Bay for the night. But only an hour out, we had to turn back. Water was coming in, and much faster than it had in the past (although not so much that we were in any danger). Once on the service dock, it didn’t take long to discover the likely cause. A rubber fitting at the top of the rudder sleeve apparently needed to be inserted into the sleeve before the quadrant was secured.

With this change in place, we were ready for another sea trial, which we tried the next day. But the conditions were flat calm and even with the assistance of the boatyard’s deadrise Jacqui Ann making waves, Orion was gliding smoothly through the water. Ironically, we were going to have to wait for worse conditions. When these arrived on Monday, Orion bounced through the waves without a drop of water leaking in. We were getting more confident that the problem was solved. We took a 2 hour ride out to meet Marianna coming in from her trip down the bay, with similar success. Looking better. Each day’s travel builds confidence in the repair, but when do you say that for sure? In the meantime, we keep checking the rudder once an hour while underway.

Finishing Up and Heading Out

Cliff tunes the rigging once Orion is in the water.

We had a few smaller projects to complete before heading out that were best done while we were at Deltaville. We had another section of caprail replaced under the port bow cleat, ensuring the spacer holding the cleat was once again replaced by one made of fiberglass-reinforced plastic, instead of stainless steel, to prevent the teak from splitting again. We also replaced the cleat in the process. Cathy then stripped the entire caprail and applied 3 coats of Cetol Natural Teak. With the damaged wood repaired and the new finish, the caprail looked the best it had in years. The final project for the boatyard was to tune the rigging once we were in the water. We hoisted the headsail again at the same time and furled and unfurled both sails to ensure they were still moving smoothly after the mast work. Cliff gave us some tips for making this job easier as well. Dave took some time to wire up the 2nd LED cabin light, giving us another extra bright light in the Main Saloon.

With some final provisioning done, and now that Marianna had caught up with us, we were ready to move south, and pretty much on schedule despite the delay at getting back in the water.

With some final provisioning done, and now that Marianna had caught up with us, we were ready to move south, and pretty much on schedule despite the delay at getting back in the water.

Boats tie up on both sides of the canal at Great Bridge.

Ahead of the Pack?

We left Deltaville on Tuesday, October 26th originally heading only for Mobjack Bay. We were still checking out the rudder for leaks and we had left later in the morning after a brief tour of Deltaville with Pat and Fred. However, we were making such good time, we decided to head for Hampton instead. We made it in well ahead of sunset and tied up on the public piers for a couple night stay. The public piers and the anchorage was full with boats staging for a trip south down the ICW and those preparing to leave for the Caribbean 1500 on Nov. 2nd. We left on Thursday for the free docks in Great Bridge, casting off just before sunrise and making it through the 11:30am lock opening along with 14 other boats. (We had come through the Gilmerton bridge at 10:30 with 17 other boats in what turned out to be about a 10 minute opening. We were shocked.) The dock was empty when we arrived, but that didn’t last. By 1pm, the dock was full and boats began tying up to the trees on the north wall of the canal.

Since we were ahead of the Nov. 1st date, the only thing we could figure is that boats were worried about the announced restrictions in the Gilmerton Bridge schedule that started on Friday. However, we learned that day that the restrictions applied only to large commercial vessels, not small boats like us.

We left Deltaville on Tuesday, October 26th originally heading only for Mobjack Bay. We were still checking out the rudder for leaks and we had left later in the morning after a brief tour of Deltaville with Pat and Fred. However, we were making such good time, we decided to head for Hampton instead. We made it in well ahead of sunset and tied up on the public piers for a couple night stay. The public piers and the anchorage was full with boats staging for a trip south down the ICW and those preparing to leave for the Caribbean 1500 on Nov. 2nd. We left on Thursday for the free docks in Great Bridge, casting off just before sunrise and making it through the 11:30am lock opening along with 14 other boats. (We had come through the Gilmerton bridge at 10:30 with 17 other boats in what turned out to be about a 10 minute opening. We were shocked.) The dock was empty when we arrived, but that didn’t last. By 1pm, the dock was full and boats began tying up to the trees on the north wall of the canal.

Since we were ahead of the Nov. 1st date, the only thing we could figure is that boats were worried about the announced restrictions in the Gilmerton Bridge schedule that started on Friday. However, we learned that day that the restrictions applied only to large commercial vessels, not small boats like us.

Marianna under sail to Elizabeth City

On Friday, we headed out to Coinjock on a beautiful warm day. We enjoyed the Friday night band at Crabby’s, while we enjoyed some of their appetizers on Marianna, which was docked just behind the restaurant. On Saturday, we had a great sail up to Elizabeth City, a new port for us. We took 2 of the last 3 spots on the free docks and were grateful to have them, since the winds were going to blow pretty hard for the next couple of days.

Elizabeth City is famous on the ICW for its Rose Buddies greeting crew.

We took advantage of our couple of days on the dock to tour the town and visit the wonderful Museum of the Albemarle just off the dock. We were glad we manage to work this visit in to our schedule this year.

Our middle grandson picks out his pumpkin.

Friends and Family

With the arrival of fall came some quickly falling temperatures and lots more rain than we had had. We were glad then for the chance to get away for a couple of weekends to visit our grandchildren and participate in some fall rituals with them. We helped pick pumpkins and enjoyed the Hampton Halloween festival. We were endlessly grateful to Steve on Bay Dreamer who picked us up in Deltaville when we couldn’t find a car rental on such short notice for the Halloween Festival. (We had thought we would be in Hampton with Orion.) He put us and 2 of our grandsons up at his house and allowed us to continue what has become an annual tradition of trick or treating in Hampton.

With the arrival of fall came some quickly falling temperatures and lots more rain than we had had. We were glad then for the chance to get away for a couple of weekends to visit our grandchildren and participate in some fall rituals with them. We helped pick pumpkins and enjoyed the Hampton Halloween festival. We were endlessly grateful to Steve on Bay Dreamer who picked us up in Deltaville when we couldn’t find a car rental on such short notice for the Halloween Festival. (We had thought we would be in Hampton with Orion.) He put us and 2 of our grandsons up at his house and allowed us to continue what has become an annual tradition of trick or treating in Hampton.

Rusty Tom and Cathie in Rusty and Joy’s new home.

Joy and Rusty on Slow Dancin’ came to our rescue during the cold snap in mid-October and allowed us to stay at their beautiful new home for a couple of nights and warm up. One of those nights we enjoyed the company also of Tom and Cathie from Interlude and Corning and Tita from Blessed Spirit who were starting out on their journey south.

Fred and Debbie from Early Out at Great Bridge.

As we traveled out of Deltaville on our first day out, we were hailed by Fred and Debbie on Early Out, who had just left Deltaville themselves. (They had just installed a new VHF and were shocked to hear Marianna and Orion on the radio, as if they were still in Cat Island.) We met up with them in person at Great Bridge and spent an evening together.

Moving On

We’re continuing to move south, not well ahead of the pack, but hopefully still in the warm weather.

Moving On

We’re continuing to move south, not well ahead of the pack, but hopefully still in the warm weather.